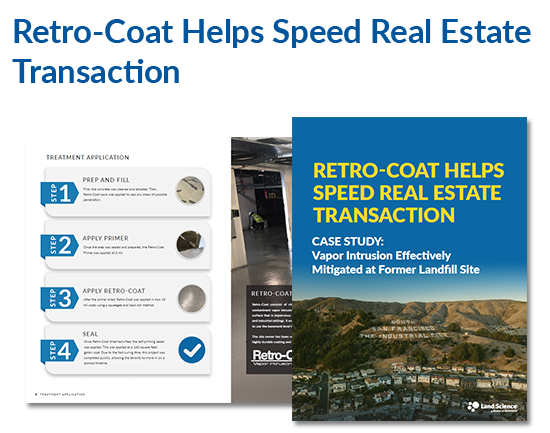

Case study highlights:

-

Retro-Coat functioned as a vapor intrusion mitigation membrane as well as a long-lasting coating for the basement level

-

Retro-Coat was chosen as the most feasible and effective treatment due to compatibility with pre-existing methane mitigation system components

-

Retro-Coat is resistant to harmful methane gas intrusion and is a wearing surface, meaning no additional concrete protection is necessary

-

The updated vapor intrusion mitigation system allowed for the new tenants to move in quickly

An office building located on the San Francisco Peninsula is located on top of a capped landfill which is a known methane producer. After a recent change in ownership, it was important for the new owner to update the vapor mitigation system to ensure the tenant’s safety from any harmful vapor intrusion. Engineering and consulting firm Langan proposed using Retro-Coat Vapor Intrusion Coating System because of its proven resistance to harmful vapors and its durability. The owner was thoroughly pleased with this application because it accomplished two goals with a single product: it mitigated the harmful vapor intrusion and provided a durable coating for the floor of the basement level. Retro-Coat’s multi-functionality saved the site owner time and money.

Complete the form on this page to download the case study.